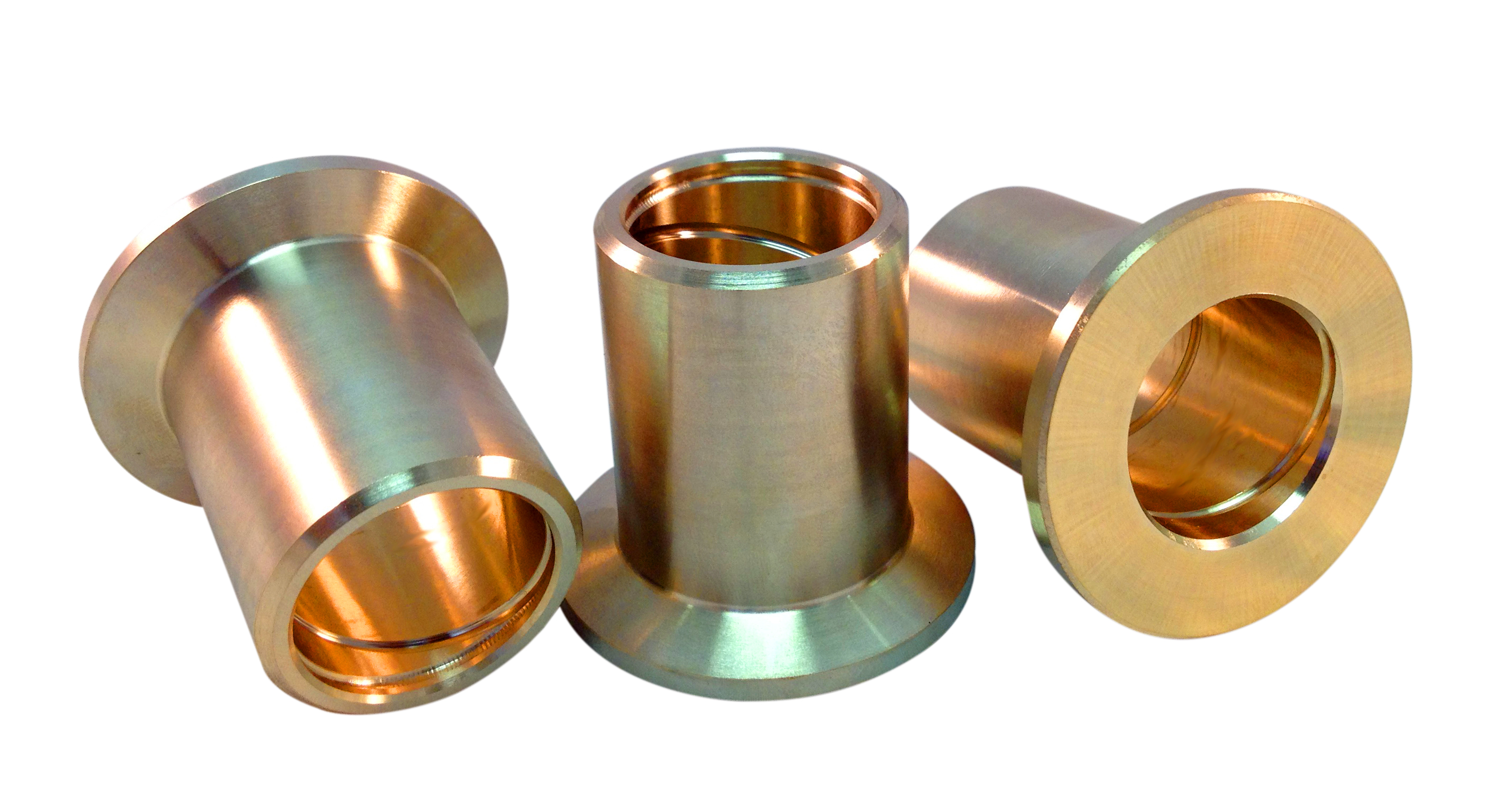

Leaded Bronze Bushings

Leaded Bronze Bushings

- Description

- Technical Specification

features

The lead content in the BP10 alloy is between 8 and 11 percent. Tin bronzes with high lead content are free cut and retain favorable thermal conductivity and good lubrication due to lead content.

Tin lead bronzes such as BP10 are ideal for bearing applications where there could be a loss of the lubrication limit. These alloys have excellent performance in unforgiving environments where there may be foreign matter, such as dirt and other foreign materials.

Alloys with a high lead content can wrap foreign matter due to its malleable nature and, in doing so, protect the wear surface of a coupling part, such as a shaft bearings for ships.

Chemical composition

|

%

|

Cu

|

Neither

|

P

|

Pb

|

Sn

|

Zn

|

Al

|

Fe

|

S

|

Sb

|

Others

|

Si

|

|

Min. |

78 |

- |

- |

8 |

9 |

- |

- |

- |

- |

- |

- |

- |

|

Max. |

82 |

0,5 |

0,1 |

11 |

11 |

0,8 |

0,005 |

0,7 |

0,08 |

0,5 |

- |

0,005 |

Chemical composition according to ASTM B505 / B505M-18